We offer innovative machine solutions for the recycling industry to contribute to a sustainable future. We adopt an environmentally friendly business model by helping to protect natural resources and recycle waste.

Adamag recycling

#wesolveitwithadamag

Waste into the Future

#recyclingwithadamag

Eco-Friendly Profit

#adamagandenvironment

Recycling

#respectfornaturewithadamag

As Adamag, we initiate the transformation with the innovative machine solutions we offer for the recycling industry and build a sustainable future together. At every step, we contribute to the protection of natural resources with environmentally friendly technologies. With our high-tech devices such as Eddy Current, we help recycle waste by making your recycling processes more efficient and effective. We are proud to work with you to build the world of the future today.

The manual cleanable belt-mounted electromagnetic holder is designed to capture iron and iron compounds

(magnetic metals) in materials being transported on conveyors. Its design can be customized based on the

width of the conveyor belts and the height at which materials are transported.

This holder is suspended above the conveyor belt and utilizes coils to create a magnetic attraction.

As materials pass through the conveyor, the electromagnetic holder effectively attracts and collects iron

and ferromagnetic materials on its lower surface. This helps maintain the integrity of the transported materials

and prevents metal contamination during the conveying process.

It is designed from high magnetic field NdFeB (Br: 14400-14800) magnets.

It is hung on conveyor lines to capture unwanted metals in the product.

Compared to St.Ferrite magnet groups, its magnetic field and attraction distance are closer.

The other application method is positioned at the end of the line, allowing the product coming

from the belt to flow by contacting the magnetic plate.

Thus, it reduces the leakage rate of very small metal particles. Points with metal complaints

in the current process can be observed and replaced with appropriate dimensions.

Advantages;

- High magnetic field,

- Micronized size metal particle capture,

- Food safety

- Portable,

- Easy to clean,

- Certified with magnetic field guarantee

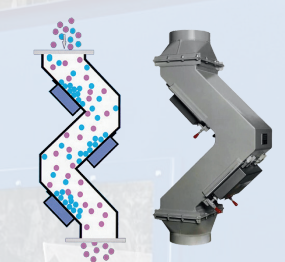

Cascade magnets are a special system designed

to separate unwanted magnetic particles from the material in

gravitational systems by means of the magnets on the surface as

it passes through the hump magnet.

- Low operating costs

- Easy cleaning

- Special sizing according to customer requirements

- High separation efficiency

- High magnetic field

A magnetic grate of a star design for the hoppers

of injection moulding machines is intended for the separation

of iron tramp from free-flowing dry materials (such as regranulates,

crushed plastic materials, plastic crumb, rejected mouldings etc.).

The magnetic grid protects the moulding machines (with standard cone hoppers) and

other processing equipment from damage by ferromagnetic particles.

Magnetic Trap Filter provides magnetic protection for liquid lines

and processing equipment with permanent magnets.

Magnetic trays preserve product purity by separating small particles of magnetic scale,

rust, and fine iron contamination.

Bullet type magnetic filters ,can be used to remove

unwanted iron particles such as iron and steel from granules,

fibers, and coarse materials in high-capacity free-fall lines.

They are used in various industries including wholesale, animal feed,

plastics, ceramics, and recycling, among others.

Magnetic bar magnets retain the invisible iron dust eroded from the system

and ensure a high degree of impurity and cleanliness.

- Manufacturing option in requested dimensions

- Applicability and ease of installation to your existing system

- Easy to clean.

- High resistance to corrosion, suitable for food

- Guaranteed maximum magnetic field on the rod surface.

It is used to retain iron and iron compounds (magnetic metals) in the transported material during transportation on conveyors.

It is possible to design the conveyor belts in any size, depending on the width and the height of the transported material.

The over-the-belt manual electromagnetic gripper suspended on the conveyor belt, the attraction feature created by the coil inside,

attracts the iron and ferromagnetic materials passing through the conveyor and ensures that they are collected on the lower surface of the over-the-belt electromagnetic gripper.